Key Features

Designed for wine bottles, cans, jars, etc.

Label up to 600 containers per hour

Apply one or two labels per container

Easily and consistently apply labels to cylindrical objects

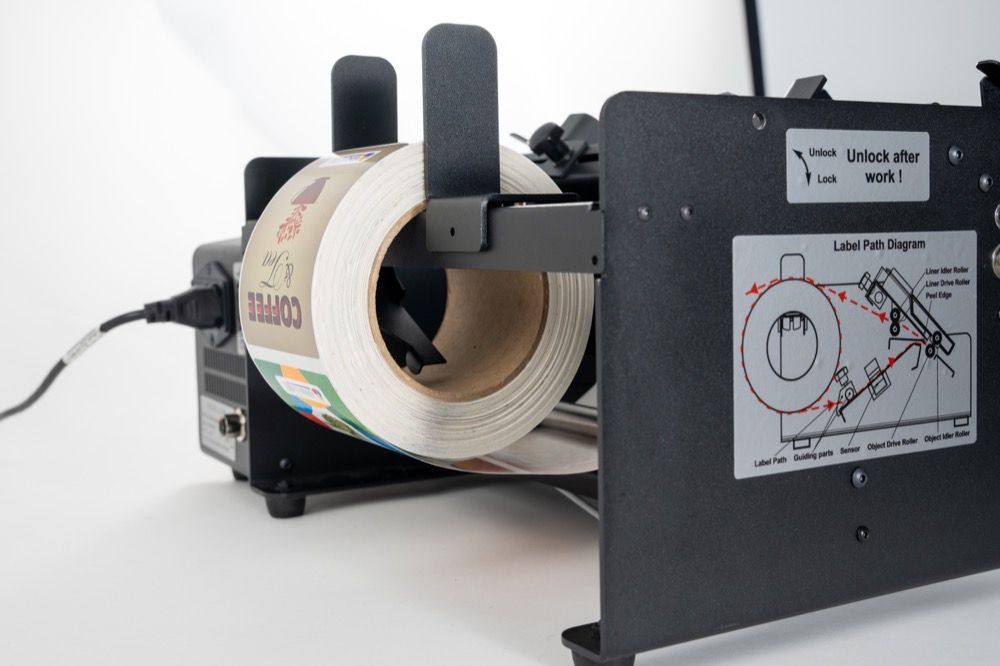

The A200 is a semi-automatic labeling machine designed for applying labels on rolls to bottles, cans,

jars, and other types of cylindrical containers. Both single and front-and-back labels can be applied

with a simple push of a button, or with the included foot pedal.

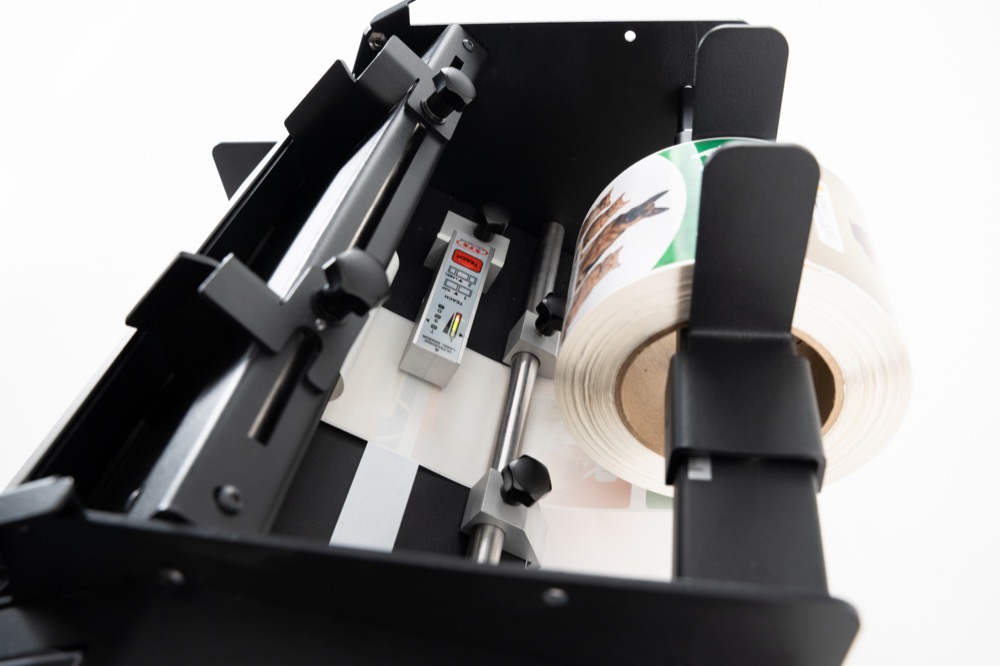

An easy-to-use calculator is available to quickly determine values for perfect placement and gap

widths. The ultrasonic media sensor is easily trained to detect gaps in a wider range of media than

mechanical flag sensors common in other applicators, allowing the A200 to perform consistently, even

on thin materials. Labels are applied evenly, efficiently, and with consistent accuracy.

A200 Bottle Label Applicator

2 operation modes

Choose between simple push button or hands-free foot pedal operation

Digital LCD touch panel

Simple-to-use digital display

panel shows status information and facilitates easy setup

Ultrasonic sensor Reliably sense gaps in a wide range of media Small to large sizes

Compatible container sizes ranging from: 1 to 6.3 in (25-160mm) in diameter

Supply voltage: North America – 110V AC, 60 Hz

Europe, Middle East, Asia – 220V AC, 50Hz

Label width: 25 to 150mm (1 to 6 inches)

Label length: 25 to 500mm (1 to 19.68 inches)

Label gap: >2.5mm (.1 inches)

Dispensing speed: 0.1m/sec (4 in/sec)

Warranty: One year

Dimensions: 365mm (14.4″) W, 245mm (9.5″) H, 330mm (13″) D

Weight: 12kg (26.5 lbs)

Container diameter: 25 to 160mm (1 to 6.3 inches)

Container height: 80 to 240mm (3.15 to 9.45 inches)

Label roll diameter: <200mm (7.87 inches)

Core size: 46 to 76mm (1.8 to 3 inches)